A colleague mentioned that he had an old bass which has no frets... not because it's a fretless bass because the previous owner had pulled them all out! He asked me if I would be able to fit new frets and I agreed. This is a Ibanez Blazer serious bass, a serious contender of the Fender P bass I'm told. It's a well worn but solid guitar.

The guitar itself has been modified in the past, there is a non standard pickup installed and the pickguard has been cut down to bare minimum. There is also a plate on the back of the guitar which is completely nonstandard.

The first thing I noticed is how long the scale length is compared to an Encore bass I own. I started by cleaning out the existing slots with a fine saw then blowing them out with compressed air. I measured the width of the marks left by the previous frets and sourced so fret wire to match.

I profiled the fret wire and cut 21 pieces to size and then began installing them with the assistance of some super glue. I don't want the new frets coming lose in the old slots.

It took a few hours to install all 21 frets but I wanted to make sure each one was seated as well as possible.

I then trimmed the overhang as close as I could and started filing the frets as close to flush to the neck as possible. I have to consider the fact that this is a maple neck and it has been lacquered so I have to be careful not too remove any of the finish. Another option would be to rub the old finish back and respray but that changes the scope of the job completely.

Once the edges were made flush I made the neck as flat as possible by adjusting the truss rod to remove the natural bow in the neck. I then marked the face of each fret with blue indelible marker and started leveling the frets relative to each other using a straight edge with sandpaper double sided to the flat edge.

Once I have removed a little of the blue pen across the face of each fret I know that there are no high or low spots across the entire neck.next I have to re-crown each fret so I marked each fret again with blue pen and then, after masking the face of the neck, I took a modified triangular file and started re-profiling each fret.

I did this along the top of each fret and then put an angle on the edges of each of the frets and moved onto progressively finer grades of sand paper to remove the tool marks left by the course crowning file.

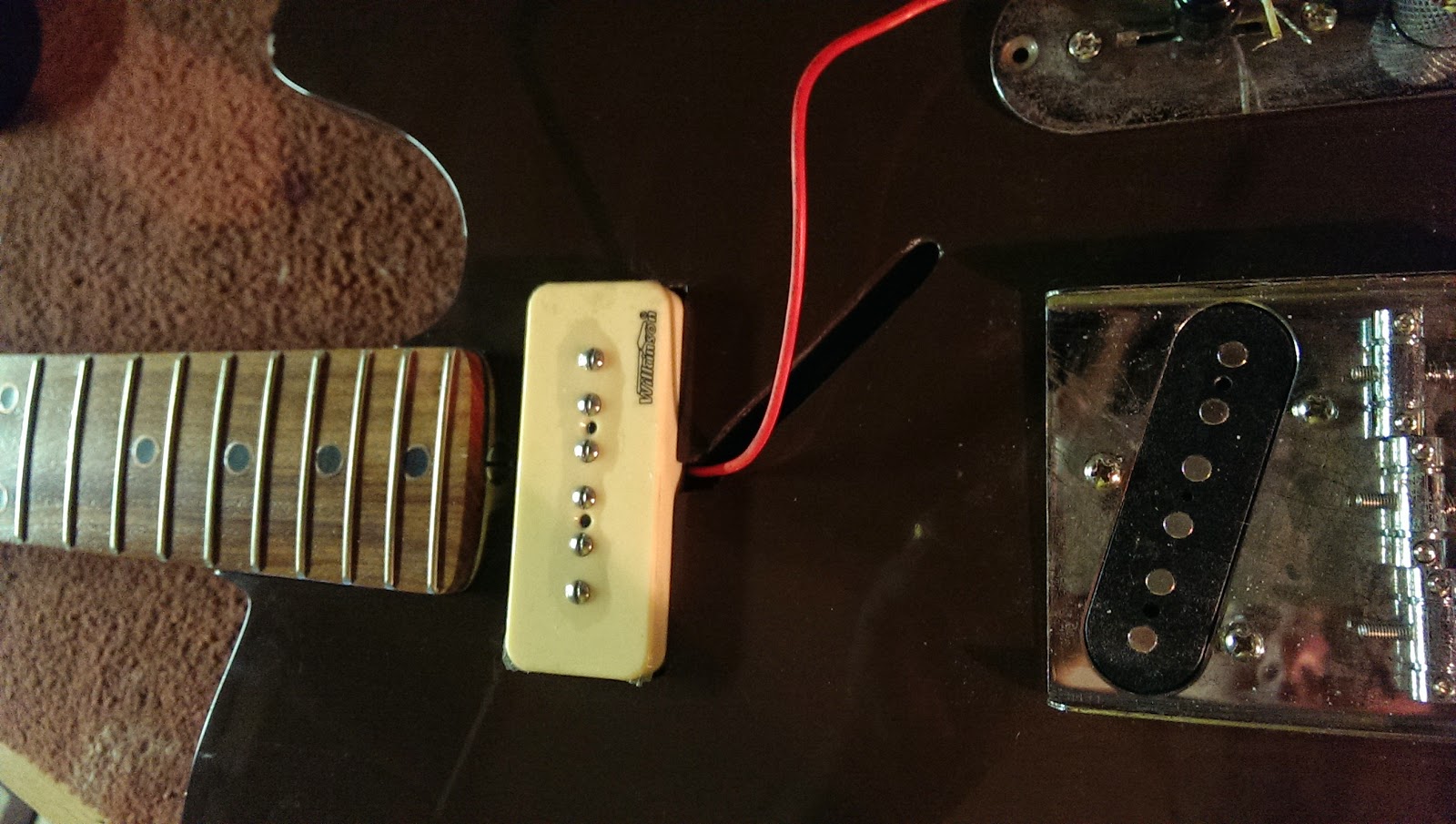

Once I had sanded each fret down to 1500 grit sand paper I moved onto abrasive polishing compounds using my dremel tool giving each fret a beautiful shine. Before I started to refit the neck and set everything up I thought I would have a look under the two covers.

To my surprise I found a 9v battery under the rear cover implying that the pickup must be a passive one, looking under the front cover I found that the jack socket it a stereo one rather than mono.

It would be fascinating to know a little bit more about the set up of the electrics but that is something for another day. I replaced the battery as a courtesy and reassembled the guitar.

I had chosen a string gauge as per the factory specifications from the Ibanez website and adjusted the string height as per the factory specs. I check intonation and finally gave everything a quick polish and test.

The frets look like they have always been there. By selecting a gauge of wire that matched the original width there is not much to give away the fact that this is a re-fret. It was difficult to file the frets flush to the sides of the neck without damaging the existing finish but overall I am very pleased with this and hope the owner is as he has a fine instrument here.